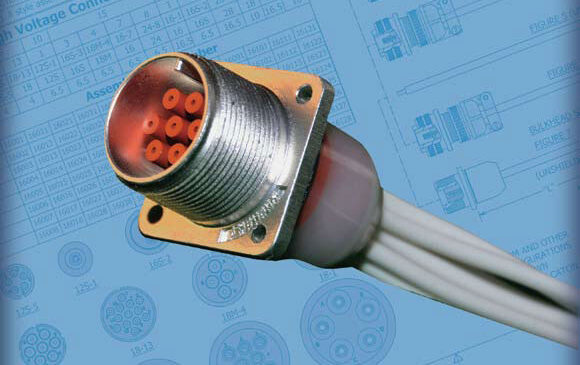

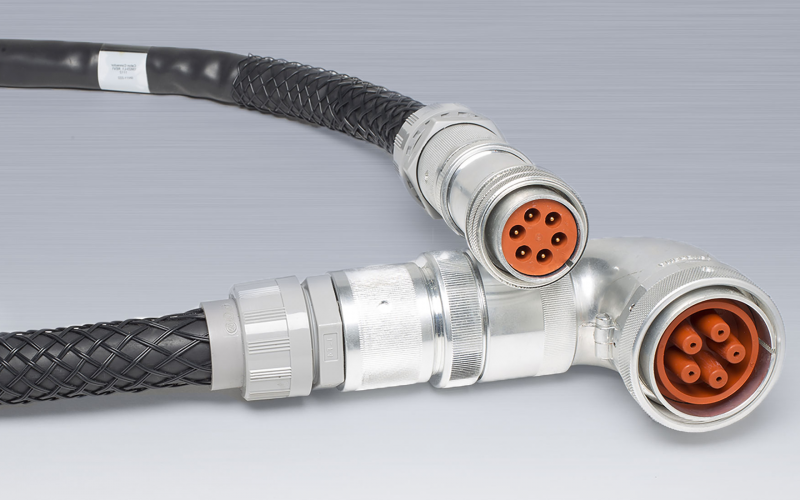

Threaded Connectors

To ensure a safe connection when installing high voltage cable assemblies as well as ensuring an environmentally sealed connection, Caton uses a screw-down mechanism on its 16 series, 17 series, and 19 series high voltage cable assemblies. When mated, these connectors ensure a safe, tamper-free connection. The 16 and 19 series use metal connectors adopted from industrial and military applications. A significant benefit of using these screw-type connectors is that the connection is not going to come loose inadvertently. Although this safety comes at the cost of connection speed, these style connectors are mostly used in applications where there will be limited connecting and reconnecting.

Caton has developed a bayonet-style connector that meets the same performance specifications as the traditional screw-type high-voltage connector for a cable assembly that will be connected and unconnected more frequently. The bayonet-style coupler for the 16 series utilizes a precision machined connector with roller bearings to aid in the smooth mating action and to lock into place when fully mated.

Push-Pull Connectors

Caton has developed the 14 series cable assembly for a quick high-voltage connection. The 14 series features a tapered conical interface with a molded-in locking feature to ensure a safe, reliable connection. The entire connector body is molded in high-performance silicone rubber to ensure high-voltage performance and reliability. The 14 series is commonly used in applications requiring frequent connection and reconnection as it is simply a push-pull mating connector.

Connector Specification Considerations

There are many considerations when specifying a circular connector for your application. The performance requirements, physical and dimensional requirements, and constraints, electrical requirements, regulatory requirements, handling and packaging requirements all must be laid out in the scope of the project. Caton’s connector design team has over 150 years of combined experience developing interconnects for the most challenging applications.