Pre-Designed Solutions

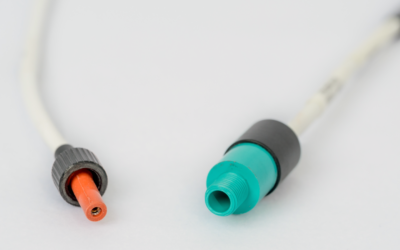

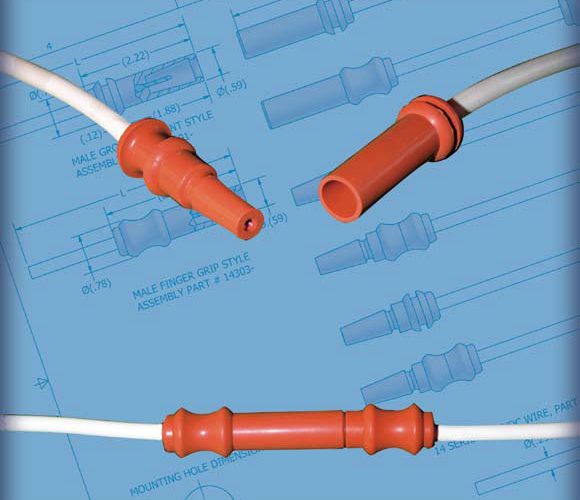

14 Series

- 10-60 kVDC

- Inline & Panel Mount

- Push-Pull Mating

- Single-Conductor

17 Series

- 10-50 kVDC

- Inline & Panel Mount

- Screw Mating

- Single-Conductor

19 Series

- 60 kVDC

- Panel Mount

- Screw Mating

- Single-Conductor

16 Series

- 5-50 kVDC

- Inline & Panel Mount

- Screw & Bayonet Mating

- Multi-Conductor

High-Voltage Wire

- 10-80 kVDC

- 22-8 AWG

- 9 Standard Designs

14 Series High Voltage Connector

General Specifications

| 1.0 Electrical (When Properly Mated) | |

| 1.1 Operating Voltage | 10-60 kVDC |

| 1.2 Current: | 4-10 AMPS |

| 2.0 Mechanical | |

| 2.1 Style: | Panel Mount & Finger Grip |

| 2.2 Plug Termination: | Bonded directly to the Cable |

| 3.0 Environmental | |

| 3.1 Operating Temperature Range: | -55ºC to +125ºC |

| 4.0 Materials | |

| 4.1 Connector Body: | Silicone Rubber per A-A-59588, Class 2B (ZZ-R-765) |

| 4.1.1 Male Connector: | Color Red, Durometer, 70 Shore A |

| 4.1.2 Female Connector: | Color Red, Durometer, 50 Shore A |

| 4.2 Pin Contact: | Hard Brass per QQ-B-626 |

| 4.3 Socket Contact: | Beryllium Copper Alloy, Grade M33-25 or M173 |

| 4.4. Pin and Socket: | Gold Plated per MIL-G-45204, Class 1, Type II |

| 4.5 Wire: | Tin or Silver Plated Copper, Silicone Insulation10 kVDC, 20 AWG, 0.100 Diameter30 kVDC, 18 AWG, 0.200 Diameter40 kVDC, 16 AWG, 0.295 Diameter |

Technical Features

- No-shell design

- Quick connect & disconnect

- Voltage ratings of 10-60 kVDC

- Amperage ranges from 4-10A

- Tapered conical interface

- Panel mount & finger grip

- Styles available in all voltage configurations

- Double ended designs available

Applications

- Land & airborne radar systems

- Harsh environments

- CRT & heads-up cockpit video display

- High-vibration applications

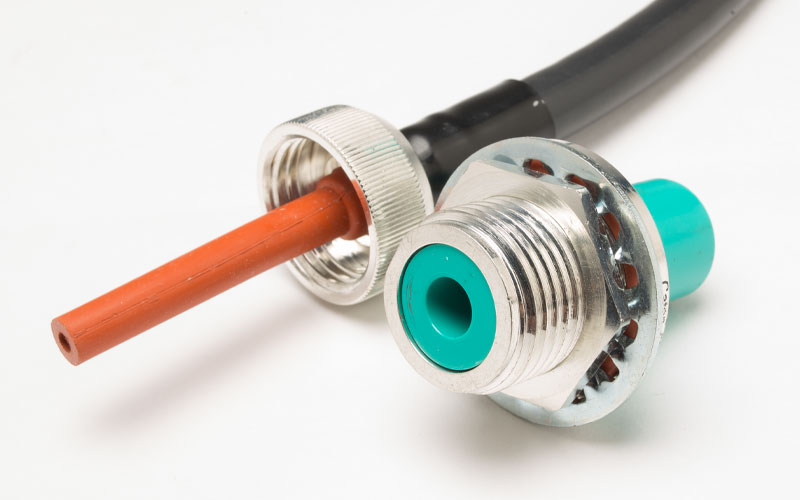

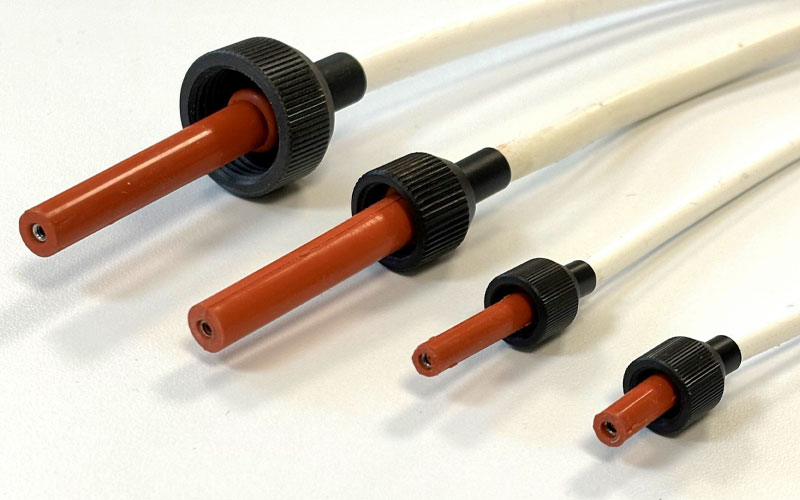

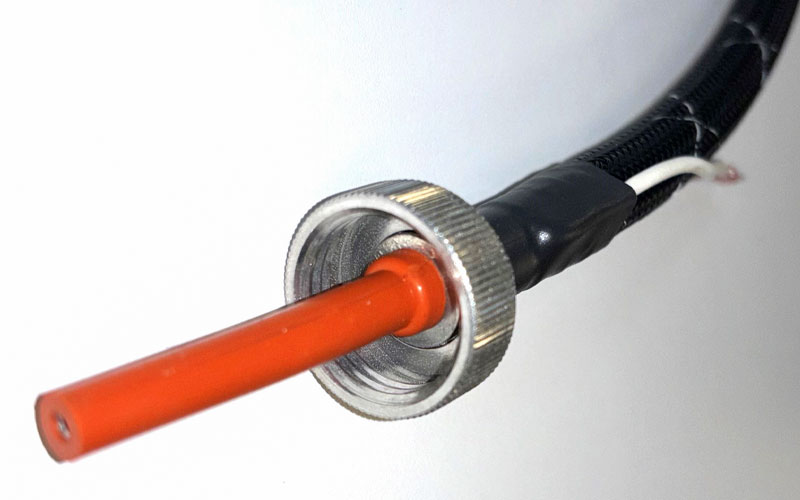

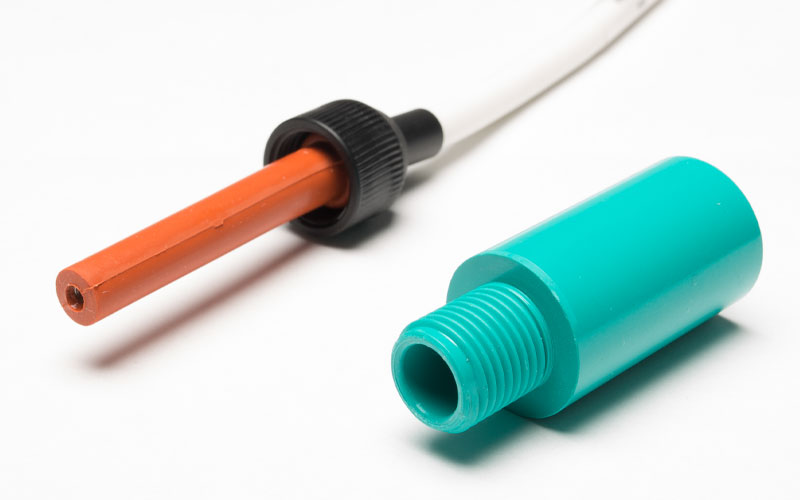

17 Series High Voltage Connector

General Specifications

| 1.0 Electrical | |

| 1.1 Operating Voltage | 10-50 kVDC |

| 1.2 Current: | 6.5-10 AMPS |

| 1.3 Corona Resistant: | Tapered Interfacial Seals |

| 2.0 Mechanical | |

| 2.1 Style: | Bulkhead and Inline Screw Coupling |

| 2.2 Termination: | Resilient Silicone Plugs Molded Directly to the Cable |

| 3.0 Environmental | |

| 3.1 Altitude: | Sea Level to 70,000 feet* |

| 3.2 Operating Temperature Range: | -55ºC to +125ºC |

| 4.0 Materials | |

| 4.1 Connector Body Plug: | Silicone Rubber per A-A-59588 (ZZ-R-765), Class 2B, Color; Red, Durometer; 70 Shore A |

| 4.2 Connector Body Receptacle: | Thermoset Diallyl Phthalate Per ASTM D 5948-96 (MIL-M-14), Color; Green |

| 4.3 Unshielded Assemblies | |

| 4.3.1 Coupling Rings and Ferrules: | Polycarbonate Per ASTM-D3935 (L-P-393) |

| 4.4 Shielded Assemblies | |

| 4.4.1 Coupling Rings and Ferrules: | Hard Brass Per QQ-B-626, Tin Plated Per ASTM B 545 (MIL-T-10727) |

| 4.5 Jam Nut Receptacles: | Hard Brass Per QQ-B-626, Tin Plated Per ASTM B 545 (MIL-T-10727) |

| 4.6 Cable: | Tin or Silver Plated Copper, Silicone Insulation |

| 4.7 Cable Shielding: | Braided Tinned Copper Per A-A-59569 (QQ-B-575) |

| 4.8. Cable Jacket (Shielded Assemblies Only): | Silicone Rubber Per A-A-59588 (ZZ-R-765), Class 2B, Color Black |

Technical Features

- Reliable and cost effective

- Shielded & Unshielded variations

- Voltage Ratings of 10-50 kVDC

- Corona-Resistant Designs

- Exclusive Caton Tapered Conical Interface

Applications

- Power Supplies

- Satellite NAV systems

- Medical Scanning Equipment

- Laser Equipment

- Land and Airborne Radar Systems

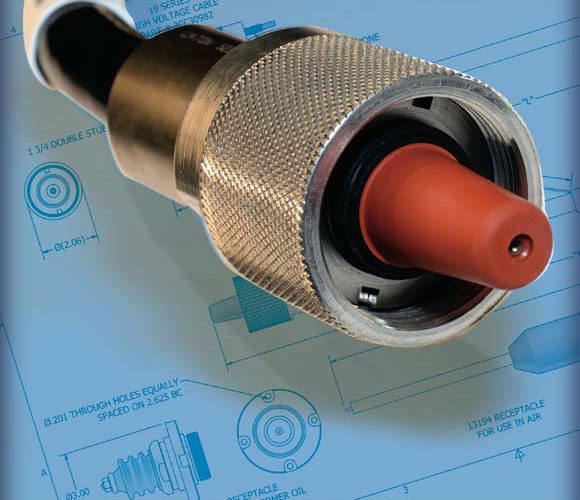

19 Series High Voltage Connector

General Specifications

| 1.0 Electrical | |

| 1.1 Operating Voltage | 60 kVDC, 20 kVRMS |

| 1.2 Current: | 26 AMPS |

| 1.3 Corona Resistant: | Tapered Interfacial Seals |

| 2.0 Mechanical | |

| 2.1 Style: | Bulkhead and Inline Screw Coupling |

| 2.2 Termination: | Resilient Silicone Rubber Insulator Molded Directly to the Cable |

| 3.0 Environmental | |

| 3.1 Altitude: | Sea Level to 70,000 feet |

| 3.2 Operating Temperature Range: | -55ºC to +125ºC |

| 4.0 Materials | |

| 4.1 Connector Body Plug: | Silicone Rubber per A-A-59588 (ZZ-R-765), Class 2B, Color; Red, Durometer; 70 Shore A |

| 4.2 Connector Body Receptacle: | Thermoset Diallyl Phthalate Per ASTM D 5948-96 (MIL-M-14), Color; Green |

| 4.3 Cable: | Silver Plated Copper, Triple Extruded Silicone Insulation |

| 4.4 Cable Shielding: | Braided Tinned Copper Per A-A-59569 (QQ-B-575) |

| 4.5. Cable Jacket (Shielded Assemblies Only): | Silicone Rubber Per A-A-59588 (ZZ-R-765), Class 2B, Color Black |

Applications

- Power Supplies

- Ground Radar Installations

- Shipboard Power Systems

- Electron Microscopes & Accelerators

- Electron Beam Scanning Equipment

Technical Features

- Corona Free Operation

- High Pulse Applications

- High Temperature

- High Altitude Applications

- Operating Voltage to 60 kVDC

- Exclusive Caton Tapered Conical Interface

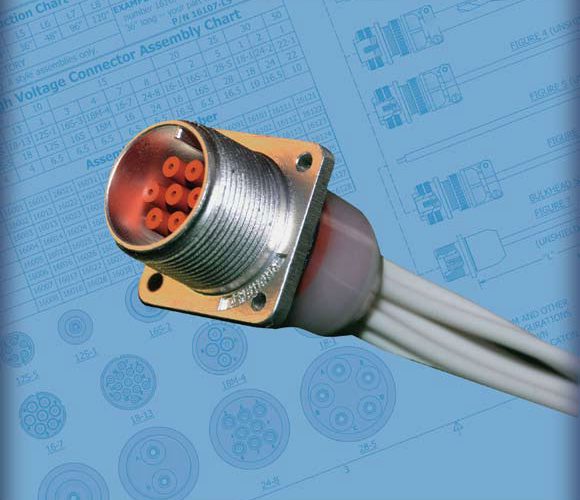

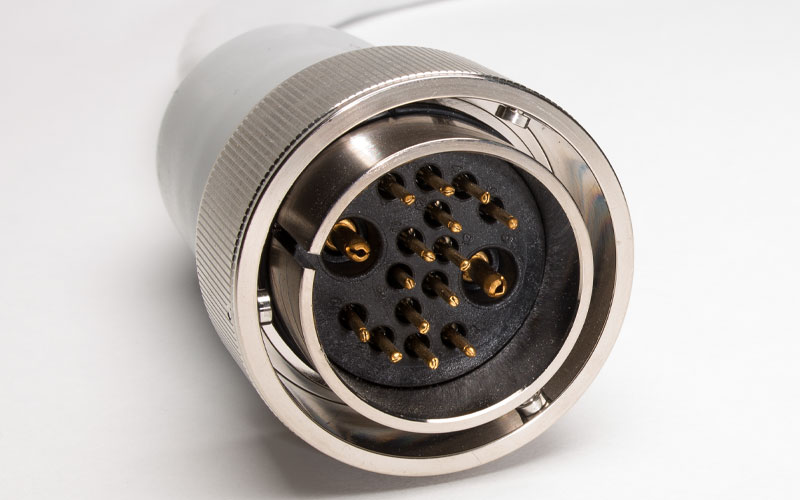

16 Series High-Voltage Connector

General Specifications

| 1.0 Electrical | |

| 1.1 Operating Voltage | 5-50 kVDC |

| 1.2 Current: | 4-85 AMPS |

| 1.3 Corona Resistant: | Tapered Interfacial Seals |

| 2.0 Mechanical | |

| 2.1 Style: | Bulkhead and Inline Screw Coupling |

| 2.2 Termination: | Resilient Silicone Rubber Inserts, Encapsulation Bonded Directly to the Wire |

| 3.0 Environmental | |

| 3.1 Altitude: | Sea Level to 70,000 feet |

| 3.2 Operating Temperature Range: | -55ºC to +125ºC |

| 4.0 Materials | |

| 4.1 Connector Body: | Die Cast Aluminum Per QQ-A-591 |

| 4.2 Shell Plating: | Bright Cadmium Per QQ-P-416, Class 2, Type II** |

| 4.3 Connector Inserts: | Molded Silicone Rubber Per A-A-59588 (ZZ-R-765), Class 2B |

| 4.3.1 Male Insert Molding: | Color Red, Durometer 50 Shore A |

| 4.3.2 Female Insert Molding: | Color Red, Durometer 70 Shore A |

| 4.4 Pin Contact: | Per MIL-C-39029 or 1/2 Hard Brass Per QQ-B-62 |

| 4.5 Socket Contact: | Per MIL-C-39029, QQ-B-626 or ASTM-B196 |

| 4.6 Contact Plating: | Gold Plated Per MIL-G-45204, Class 1, Type II |

| 4.7 Wire: | Tin or Silver Plated Copper, Silicone Insulation |

| 4.8 Cable Shielding: | Braided, Tinned Copper Per A-A-59569 (QQ-B-575) |

| 4.9 Cable Jacket: | Silicone Rubber Per A-A-59588 (ZZ-R-765), Class 2B, Color Black |

Technical Features

- 19 Insert Arrangements

- 10 Shell Sizes

- Voltage Capability 5-50 kVDC

- MIL-C-5015 Aluminum shells available in a variety of finishes and plating’s

- Corona-Resistant Designs

- Low Micro-Discharge Designs

- Amperage ranges from 4 -85A

Applications

- Power Supplies

- Ship Board and Ground Radar

- Laser Equipment

- Satellite NAV Systems

- Land and Airborne Radar Systems

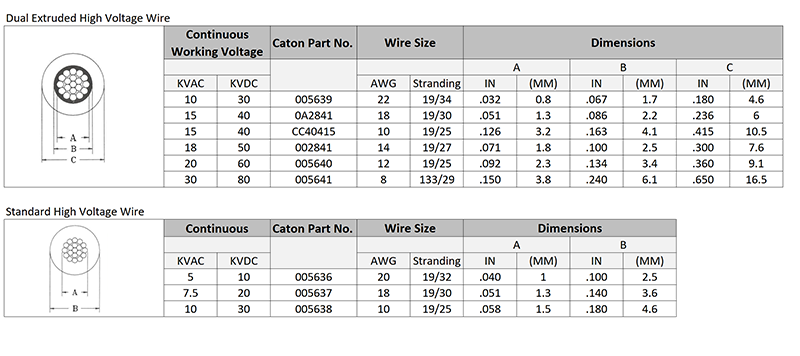

High Voltage Wire

Caton’s wide range of high-voltage silicone wire is offered in multiple sizes and configurations to meet your application. The silicone dielectric maintains excellent flexibility over an extreme temperature range and is resistant against radiation, moisture, and weathering. Being compatible with most silicone encapsulation materials, this wire makes an excellent choice for most high-voltage terminations.

General Specifications

| 1.0 Electrical | |

| 1.1 Operating Voltage | 15-80 kVDC |

| 1.2 Corona Resistant | Semi-conductive Silicone Layer |

| 2.0 Materials | |

| 2.1 Dielectric: | Silicone Rubber |

| 2.2 Semi-Conductive: | Silicone |

| 2.3 Conductor: | Tin or Silver Plated Copper |

| 3.0 Environmental | |

| 3.1 Operating Temperature Range: | -55ºC to +125ºC |